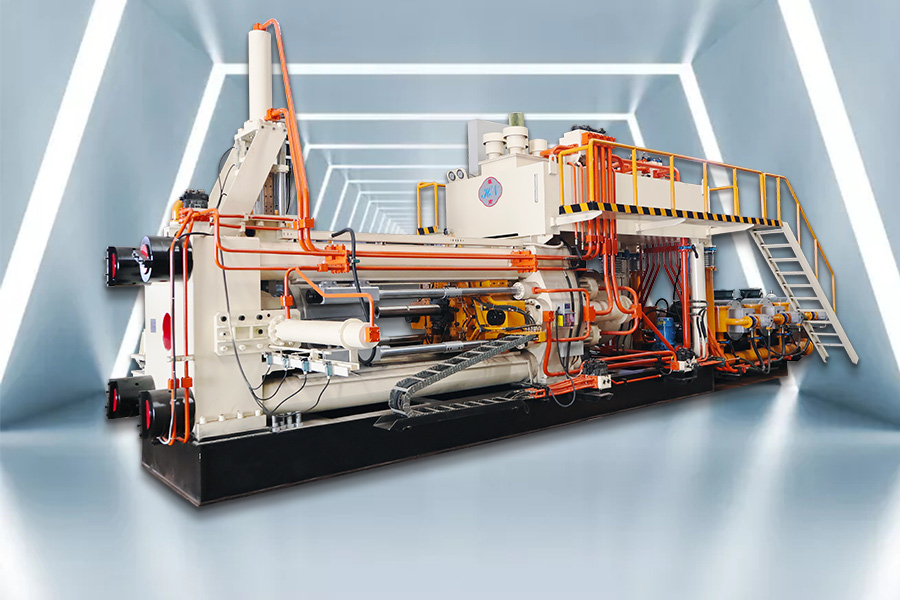

Key Components of a High-Performance Aluminum Extrusion Machine

Apr 25, 2025

As a large aluminum extrusion machine, it is equipped with various components and possesses multiple functions, making its structure relatively complex. The extrusion machine is composed of the frame, electric and hydraulic systems, conveying system, heating system, die system, control system, shearing system, etc. Among these, the frame, electric and hydraulic systems, die system, and control system are the most critical.

1、FrameThe frame is one of the most important parts of the extrusion machine: it bears the weight and impact pressure of the entire machine. It needs to be made of high-strength steel. A structurally stable frame can withstand high extrusion forces, and its load-bearing capacity is especially important for manufacturing high-strength, high-precision aluminum profiles. It ensures that the aluminum extrusion machine can stably, accurately, and continuously produce aluminum profiles, which is also a key factor affecting the service life of the machine.

The frame structure of the aluminum extrusion machine produced by our company, Huanan Heavy Industry(www.huananmachine.com), is composed of an integrally forged front crossbeam, a cast rear crossbeam, tie rods with a diameter of φ350 (material: 42CrMo), and square pressure sleeves, forming a closed prestressed composite frame. Special hydraulic preloading tools are used to apply super-pressure tensile loads along the entire length of the tie rods and compressive stress to the pressure sleeves, putting the entire frame in a prestressed state. The center distances of the four load-bearing tie rods are symmetrical with respect to the center of the press, ensuring uniform force distribution across the entire frame. This improves the precision of the extruded products. Two sets of elastic anchoring devices are installed at the bottom of the rear beam and anchored to the foundation, ensuring reliable fixation of the rear beam. The stable and sturdy frame structure is also one of the reasons why our extrusion machines have a longer service life compared to those of our peers.

2、Electric Motor and Hydraulic SystemThe extrusion machine has two power sources: electricity and hydraulics. As the driving source of the aluminum extrusion machine, the electric motor and hydraulic system require precise control and monitoring to ensure optimal performance. Key components include:

Main Cylinder

Extrusion Stem

Extrusion Container

Main Cylinder: Provides enormous extrusion force (ranging from hundreds of tons to tens of thousands of tons) to drive the extrusion stem forward. Requires high stability, sealing performance, and fatigue resistance.

Extrusion Stem (Extrusion Shaft): Transfers the pressure from the main cylinder to the aluminum billet, pushing it through the die for shaping. It must be heat-resistant and wear-resistant, typically made from high-strength alloy steel (e.g., H13).

Extrusion Container (Billet Container): Holds the heated aluminum billet and withstands the high pressure and temperature during extrusion. The inner lining must be resistant to high temperatures (400–500°C) and wear. It typically has a layered design, with a prestressed outer sleeve and a replaceable inner lining.

3、Die SystemDifferent aluminum profiles require different dies. The shape and dimensions of the die directly determine the cross-sectional shape and dimensional accuracy of the extruded aluminum. Therefore, die fabrication requires precision and stability. Dies are generally made of high-strength steel (such as H13 steel) to withstand the tremendous extrusion force.

4、Control SystemThe operation of the extrusion machine requires a complex control and monitoring mechanism. The electrical control system of our aluminum extrusion machines at Huanan Heavy Industry adopts a two-level control system based on industrial programmable logic controllers (PLCs). Sensors are arranged throughout various parts of the extrusion machine to monitor pressure, temperature, displacement, and other parameters in real time. The PLC system enables full process control of the machine.

The control panel is equipped with operation buttons, while the touch screen includes touch switches, digital displays of extrusion speed, stroke, extrusion force, extrusion container temperature, and indicators for machine status and fault alerts.

Network Supported

Network Supported